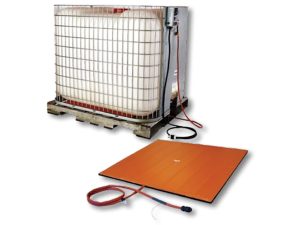

BriskHeat ATEX approved wraparound Tote and IBC heaters are designed to provide even heat distribution and maximum energy efficiency in explosive environments. With its robust construction and fully insulated design, these heaters are ideal for indoor or outdoor use and grounded for increased safety. Suitable for use on steel or plastic IBC, these heaters require an ATEX certified temperature controller.

- Temperatures up to 392°F (200°C)

- 2 built-in PT100 RTD sensors for monitoring process temperature and high-limit temperature

- IP Rating: IP65

Overview

ATEX Insulated IBC Heater. 230 VAC. 2400 W. Fits 1000 Litre Containers. Length 4,4 m. Height 100 cm. Includes 2 Built-In Ex-PT100 RTD Temperature Sensors. Maximum Operating Temperature 180°C. Maximum Ambient Operating Temperature -40°C to 60°C. 3,0 m Power Cord and Sensor Cables with Crimped Ferrule Terminated Leads. For Use in Potentially Explosive Gas and Dust Atmospheres. The Heater Must Be Temperature Controlled and Limited To The Required Temperature Class. T3. IP65. ATEX II 2G Ex e mb IIC T3 Gb, II 2D Ex e mb IIIC T120°C Db, -40°C ≤ Ta ≤ +60°C (ambient temperature), EC-type examination certificate TPS 11 ATEX 29587 011 X.

Product Highlights

- Ideal for a wide range of hazardous-area drum heating applications – ATEX Gas and Dust

- Fully insulated and water resistant – Suitable for use in outdoor or wet environments – IP 65 rated

- Operating temperatures up to 200°C (392°F) – T3

- Adjustable straps with buckles for easy on and off installation

- 2-RTD sensor system – For process and high temperature limit

Explosion protection marking:

Gas  2G Ex e mb IIC T3 Gb

2G Ex e mb IIC T3 Gb

Dust  2D Ex e mb IIIC T120°C Db

2D Ex e mb IIIC T120°C Db

-40°C ≤ Ta ≤ +60°C (ambient temperature)

System approved with an EC-type examination certificate

according to RL 2014/34/EU appendix III

EC-type examination certificate

TPS 11 ATEX 29587 011 X

Applications

Various liquids, gasses, and even solids are often stored in bulk containers. Common containers include drums, IBC tanks, and gas bottles. In order to effectively protect the contents from cold, reduce viscosity, or increase efficiency for easy dispensing, the contents must be kept warm. If the temperatures of the contents fall below desired levels, the contents could be ruined or unable to dispense at all. Many of these containers are in hazardous areas where ATEX certification is a requirement for the type of heaters permitted for use.

Frequently Asked Questions

Q: What is ATEX?

A: ATEX is a set of European directives that defines the equipment that is allowed in an environment with an explosive atmosphere. It gets its name from “ATmoshpheres EXplosibles”.

Q: How is ATEX defined?

A: ATEX is divided into two categories: – 1) Gas, Mists, or Vapors, and 2) Dusts. The first has three categories which are “0”, “1”, or “2”. The second also has three categories, and they are “20”, “21”, or “22”. The higher the number, the more restrictive the environment.

Q: How do I know if my equipment is compliant with a given environment?

A: Equipment that is ATEX-complaint will have an ATEX marking on the product. Additionally, the manufacturer will be able to produce an ATEX-compliant certificate.

Q: Who certified that equipment is compliant to specific ATEX environments?

A: 3rd-party companies that are government-accredited as “ATEX Notified Bodies” for the ATEX directives can test and approve equipment for specific standards.

Q: Who defines my company’s environmental ATEX classification?

A: The same ATEX Notified Bodies will perform inspections and define environments.

Q: Do employees need ATEX training or instruction?

A: Yes. Per government regulations, employees must be provided with all the necessary information, instruction, and training on the risks present at the workplace and the required prevention and protection measures.

Q: Do Heaters and controllers need to be approved as a system in order to be used together in an ATEX environment?

A: No. Each can be independently certified

Q: Are ATEX approvals recognized outside of Europe?

A: In some areas they are accepted, and in some areas they are not. For example, in Asia they are accepted, but in North America they are not. Local laws and regulations should be consulted.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.